Supply Chain Risk Management is an essential pillar in the field of Supply Chain Management and identifies, prevents and mitigates internal and external risks that can affect the smooth running or even the basic function of a Supply Chain. Particularly in crisis situations, i.e. when the Supply Chain is already disrupted or when identified risks indicate an immediate disruption, the continuation of SCRM measures is of great importance. The following points are particularly important with regard to SCRM in crisis situations:

- Avoiding crises if possible

- Early identification of crisis situations

- Detailed view of the Supply Chain and its structures (visibility)

- Flexible options for action

- Quick reaction time

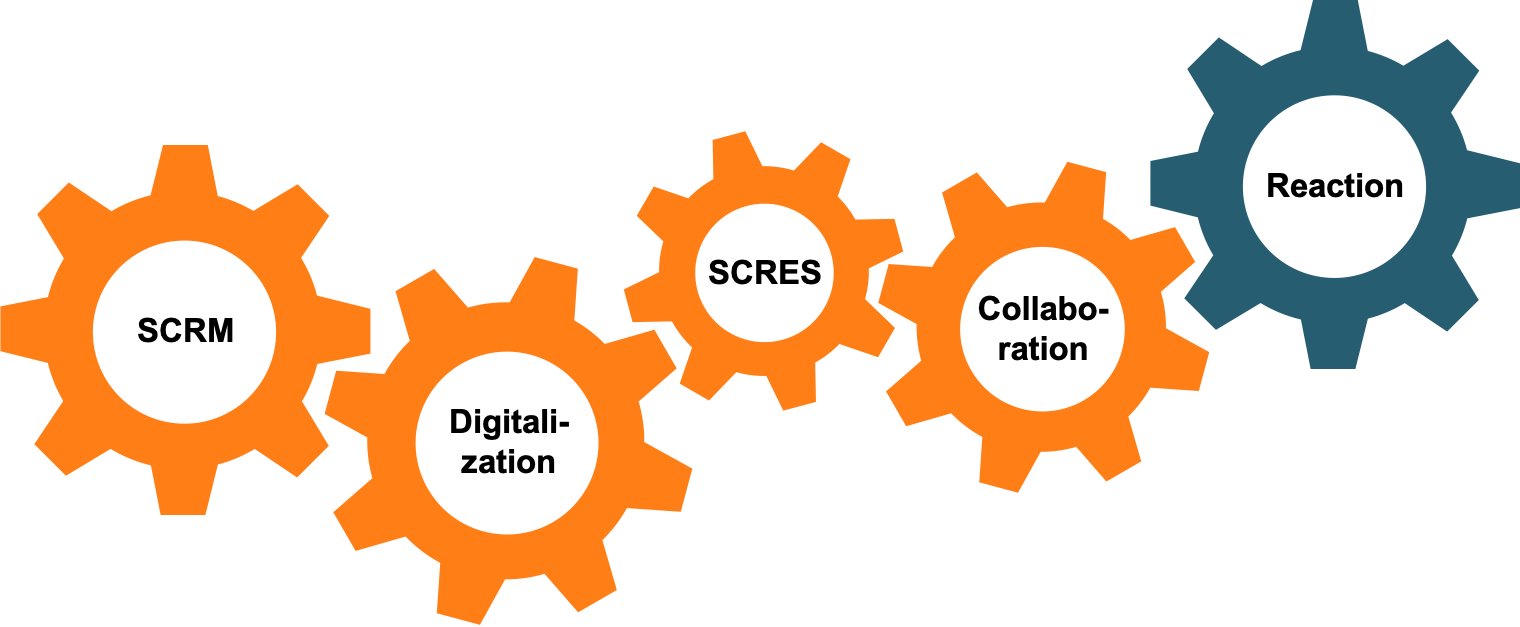

The core of the SCRM process in crisis situations is traditional SCRM, which is, however, supported by digital tools in the Pre-Crisis and In-Crisis phases. In the run-up to or at the onset of an acute crisis situation, a resiliently structured Supply Chain is advantageous, which is supported by digital options and benefits greatly from Supply Chain-wide stakeholder collaboration. The better these four factors are coordinated and implemented in a Supply Chain, the faster an adequate response can be made to a crisis situation.

Supply Chain Risk Management (SCRM)

Good and comprehensive SCRM is to be implemented iteratively in six steps and can be done systematically using standards, guidelines and best practices. For more information please refer to our SCRM Overview incl. the six steps, to the ISO 31000 Standard, as well as different Methods and Tools for a step-by-step implementation of successful SCRM.

Digitalisation

For more information on which digital tools can be used in which capacity to support SCRM, please refer to our overview of Methods and Tools as well as to the section of improving Visibility on the Supply Chain Resilience site.

Supply Chain Resilience (SCRES)

The SCRES processes and the development of business continuity plans as part of business continuity management are closely linked. Achieving a more resilient supply chain consists of four steps with respective tasks that include elements from business continuity management or collaboration. For more details on SCRES, BCM or Collaboration please refer to our detailed explanations on the respective topics.

Collaboration

To sucessfully implement Supply Chain Wide Collaboration, different Types of Collaboration as well as the closely interlinked Supply Chain Risiko Governance are to be repected.

Reaction

What should be considered when collaborating with Supply Chain partners?

Risk transparency

Crises can bring rapid changes in situations and thus also in the requirements for SCRM, so that it may be necessary to shorten the update cycle in order to create risk transparency. In the best case, companies should act on the basis of daily updated data, which underlines the advantages of digital tools.

Monitoring the liquidity situation

An assessment of the measures to be implemented in terms of their impact on the company's liquidity is imperative in crisis situations.

Demand - Supply synchronisation

In order to maintain corporate liquidity, the company's demand and supply should always be considered and aligned.

Decision-making acceleration

The short-term changes in the situation during crises also require companies to react quickly. In this case, the installation of a crisis team with the aim of accelerating decision-making can be expedient (read more).