“Resilience implies flexibility and agility.” 18, p.22

What is (Supply Chain) Resillience?

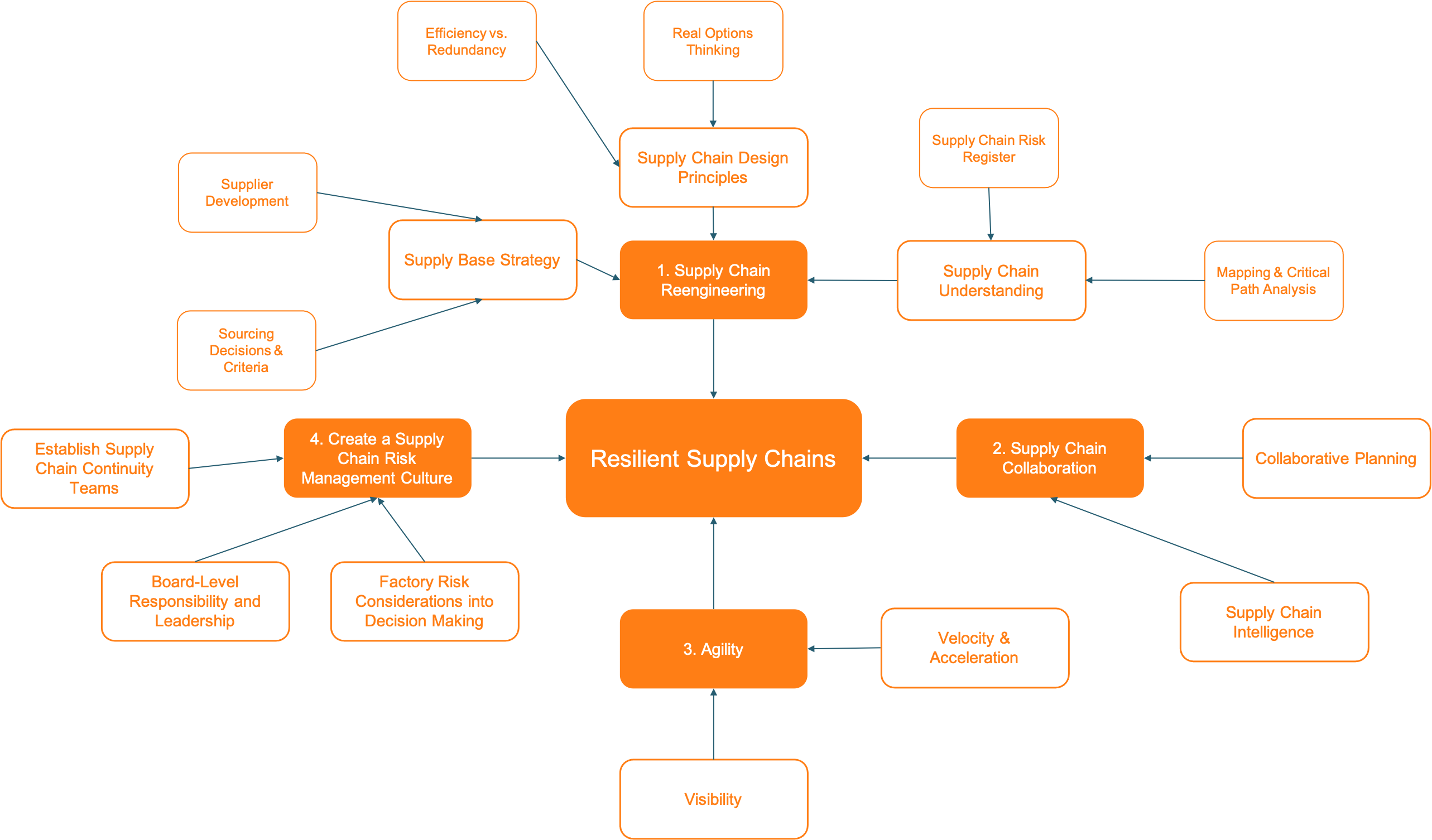

How can a resilient Supply Chain be built?

- Resilience should be designed in, meaning certain resilience features should deliberately engineered into a supply chain. 18, p.13

- Collaboration between different Stakeholders is required 18, p.13

- Ability to react quickly to a crisis. 18, p.13

- Creation of a risk management culture in the organization 18, p.13

Own Illustration of Christopher and Peck (2004) 18, p.24

1. Designing in Resilience 18, p.14

1. Understanding the Supply Chain

- You need to understand a Supply Chain first, to be able to make it more resilient

- Mapping tools can be used to make a Supply Chain fully visible and understand it

- The aim of Supply Chain Mapping is to find critical factors in a SC

- These can be long lead-times, single sources of supply, linkages with poor visibility or high levels of identifiable risk

- For a list of Tools to use for Supply Chain Mapping please refer to the section below

2. Supply Base Strategy

- Once awareness for vulnerabilites in a Supply Chain has been created decisions on sourcing stategies need to be made

- You should be aware of the risks that you could fall to

- Based on this awareness, you need to decide if you have one supplier for a part or multiple ones

3. Design Principles for Supply Chain Resilience

- “Choose supply chain strategies that keep several options open” because this can reduce the impact of a disruption

- Re-Evaluate if efficiency is always to be chosen over redundancy and balance the two by maintaining certain safety stocks where possible and desirable

2. Supply Chain Collaboration 18, p.17-18

The Aim within a Supply Chain Risk Reduction Community is to gain as much knowledge about the Supply Chain as possible.

Please refer to the list below to find more tools and guidelines on how to gain detailed insights into a Supply Chain.

3. Agility 18, p.18-21

1. Visibility

- Supply Chain Visibility describes the ability to see from one end of the SC to the other.

- To increase the Supply Chain Visibility, close collaboration between and even within companies is required, because every company or even busines unit tend to maintain their own data silos.

- Besides Information Silos, the SC Visibility can be impaired by larger inventories up or down stream of the focal firm. This is in part also responsible for the Bullwhip Effect.

- For tools on how to increase Supply Chain Visibility please refer to the list below.

2. Velocity

- Supply Chain Velocity describes initiatives to reduce the time, that any good needs to travel through the entire Supply Chain.

- The time in this case is to be understood as the time of order at the supplier until the focal firm delivers to its customer.

- To achieve more velocity in a Supply Chain, there are three foundations:

- For guideslines on how to achieve these, please refer to the list below.

4. Creating a SCRM Culture 18, p.21-22

To achieve a strong Risk Management Culture, several measures can be taken:

Additional explanations/zusätzliche Erläuterungen

| Nr. | Phase(s) | Description |

|---|---|---|

| 1 | Creating a Supply Chain Risk Management Culture | A Complete Guide to the Risk Assessment Process |

| 2 | Agility - Velocity | 5 Ways to streamline logistics processes, Steamliing Logistics Processes, Volvo Case Study on how Reduce Lead Times can change Logistics Performance, Five Steps to Achieve Supply Chain Synchronization, Reducing Non Value Added Time with 5S in Logistics |

| 3 | Agility - Visbility | 10 Steps to increase SC Visibility, Medium: 5 Ways to increase SC Visibility, Guidelines on how to deploy safe and ethical tracking of SC activities |

| 4 | Supply Chain Collaboration | McKinsey on the importance of data to gain SC insights, IBM on the importance of SC analytics to gain insights, Gartner 7 Step Plan to Drive Adoption of Supply Chain |

| 5 | Designing in Resilience | Software for Mapping Supply Chains 1, Software for Mapping Supply Chains 2, Paper on Supply Chain Mapping to Prepare for Future Pandemics |